Butt Fusion Defined

The butt fusion process is under the larger umbrella of plastic welding and involves the heating of two separate plastic components; usually either two pipes or a pipe and a fitting. Historically, this process was mainly applied to polyethylene but recently polypropylene has seen rapid growth. However, the process is general to most thermoplastic pipes. At its most simplistic level, heat is applied by an electrical heating plate to the ends of both parts simultaneously until melting occurs. Then, the heater plate is removed and pressure is applied for a specified period of time creating "weld beads”. The joint has a typical appearance when properly constructed which is used in joint inspections or audits - especially for critical applications like natural gas pipe . While the details of temperature, pressure and time will depend on the polymeric material, the basics are the same.

If you are working on a butt fusion project or have questions/issues relating to this process, contact our fusion specialists.

If you are working on a butt fusion project or have questions/issues relating to this process, contact our fusion specialists.

The joint or "weld" that is created between the two plastic components is able to withstand end loads and performs almost the same as the original pipes without the weld.

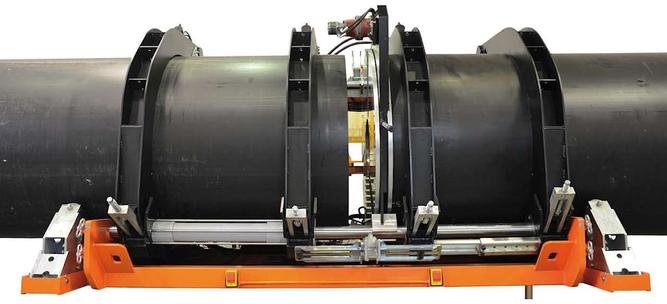

For larger pipes, a butt fusion welding machine is used to allow precise control of several additional factors including:

- ovality and alignment

- surface squareness and cleanliness

- heat soak time

- heater plate temperature

- bead width

- interfacial pressure

- cooling time

Looking for more on Butt Fusion?

- Check out Bryan Hauger's publication on additional factors that affect butt fusion. It is a must read if you're interested in this process. You can also contact us if you have any questions, we'd be happy to chat.

© Copyright Bryan Hauger Consulting, Inc., 2023. All rights reserved